The solution: transfer the speckle pattern from a stamp to the specimen surface

NASA Langley Research Center had a dilemma.

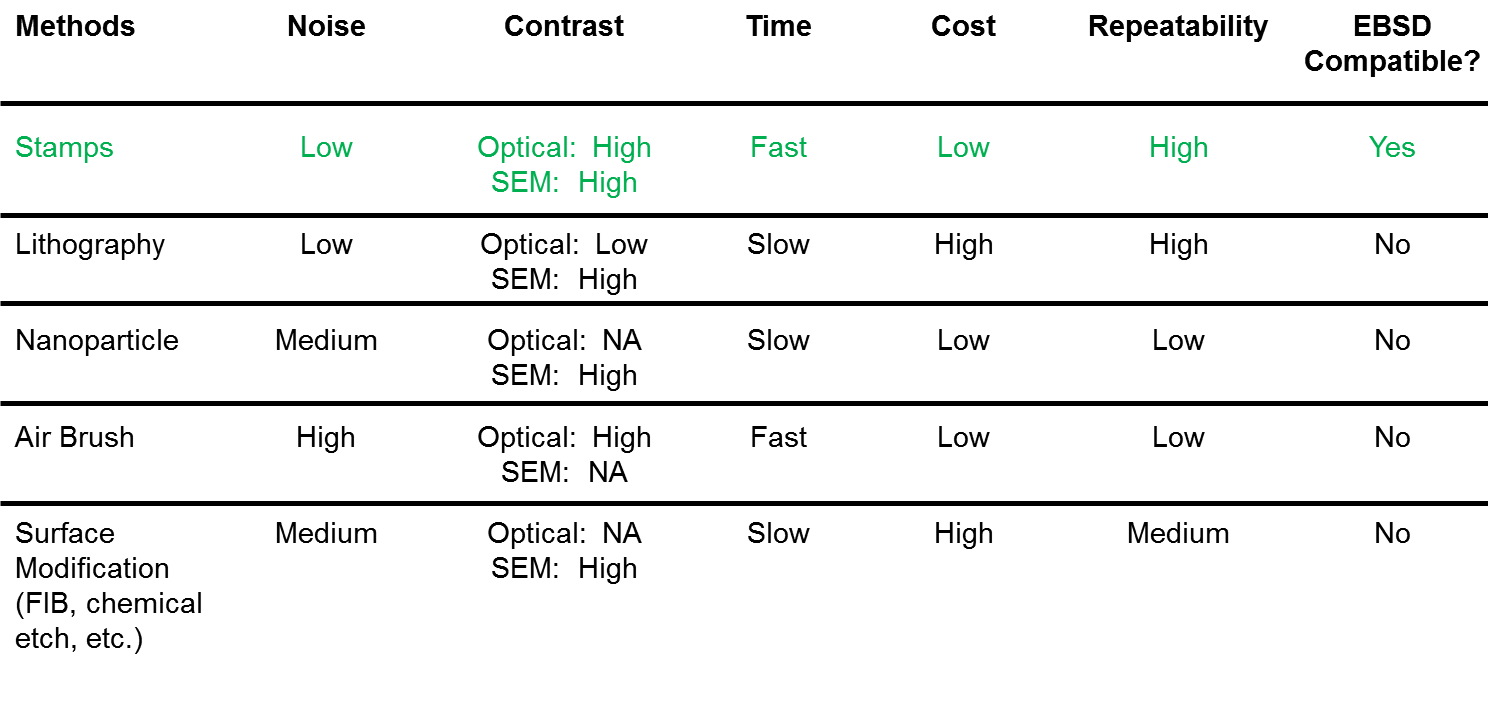

Electron beam lithography gave repeatable, designed speckle patterns - but the speckles were transparent and took many hours to process. Air bushing was fast and gave good contrast - but the speckles were too big and the pattern was not repeatable specimen-to-specimen. NASA needed to process many specimens quickly - all with the same low-noise designed micro speckle pattern.

The solution was micro speckle stamps: physical stamps that transfer designed micro patterns of ink to the specimen surface for DIC experimentation.

Since that early success, we have spent years creating micro speckle stamps for researchers in the US and around the world. Now we are offering our stamps to anyone - hassle free.

Let us make the micro speckle stamps so you can focus on your research. Just click - and your micro speckle stamps will ship within 5 business days.

1) Receive your microSpeckle Stamps 2) Apply a microSpeckle Stamp to a Specimen on a Hot Plate 3) Remove the microSpeckle Stamp. Now your specimen has a designed, low noise micro speckle pattern - without using lithography!